Thin Film Development

Zoe Barber

Much research within the Device Materials Group is based upon thin film fabrication using vapour deposition techniques, and we are further developing our deposition technology.

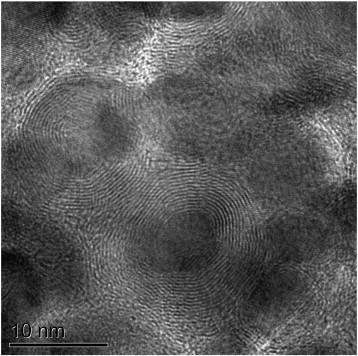

For example, an additional radio-frequency plasma between a vapour source and a substrate leads to ionisation of the depositing flux, and allows increased control during film growth. We have demonstrated the potential for fabrication of novel film structures: for example, nickel nano-particles surrounded by carbon "nano-onion" shells; and extremely porous, vertically oriented, nano-pillar arrays. By controlling the growth of materials, it is possible to explore structures and properties that would not normally occur in bulk materials.

Image: Microstructure of nickel nanoparticles surrounded by carbon "nano-onion" shells.

Recent projects have included growing both highly ordered epitaxial nitrides but also the low temperature deposition of amorphous superconductors. Often these films are then fabricated into devices such as nanowires for photon detection, or Josephson junctions and other superconducting devices. The expertise of the DMG group allows us to go from film growth to device fabrication through to testing to determine how to optimise a wide range of novel material behaviours. Research includes the control and optimisation of film growth (including plasma analysis techniques for characterisation of the deposition environment), and micro-structural and physical characterisation of the deposited film structures (requiring the highest resolution methods). This offers great potential for fabrication of a wide range of materials and composites, and investigation of further novel structures and properties.

Image: Sputtering deposition system used to grow thin films.

- D. Bosworth, S.-L. Sahonta, R. H. Hadfield, Z. H. Barber, 2015, 'Amorphous molybdenum silicon superconducting thin films', AIP Advances, vol. 5, no. 8, p. 087106 http://dx.doi.org/10.1063/1.4928285

- W.T. Jiang, N. Ullah, G. Divitini, C. Ducati, R.V. Kumar, Y.C. Ding, & Z.H. Barber, Vertically Oriented TiOxNy Nanopillar Arrays with Embedded Ag Nanoparticles for Visible-Light Photocatalysis, Langmuir 28, 5427-5431 (2012)

- W.T. Jiang, K. Senapati, L. San-Emeterio-Alvarez, N.A. Stelmashenko, H. Zhang, Y.C. Ding, & Z.H. Barber, Nanoporous metallic templates for embedded magnetic nanostructured films, Thin Solid Films 520, 533-536 (2011)

- K. Senapati, M.G. Blamire, & Z.H. Barber, Spin-filter Josephson junctions, Nature Materials 10, 849-852 (2011)

- K. Senapati, T. Fix, M.E. Vickers, M.G. Blamire, & Z.H. Barber, Structural evolution and competing magnetic orders in polycrystalline GdN films, Phys. Rev. B 83, 014403 (2011)

- K. Senapati, T. Fix, M.E. Vickers, M.G. Blamire, & Z.H. Barber, Magnetic exchange hardening in polycrystalline GdN thin films, J. Phys.: Condens. Matter 22, 302003 (2010)